Oil and natural gas comprise more than half the world’s primary energy sources as of 20191, generating approximately $4.3 trillion in revenue in 20232. While a full pivot towards cleaner and more renewable energy will take some time and effort, oil and gas-based energy can benefit from artificial intelligence, especially in two key areas: maintenance and safety.

Already, a survey found that more than 92% of oil and gas companies actively invest in AI or plan to soon3. Beyond maintenance and safety, AI offers the potential to streamline various aspects of the field, including demand forecasting, exploration, regulatory compliance, and supply chain management.

In this blog, we will describe how AI can improve oil and gas companies’ processes and save costs in these areas.

Predictive Maintenance for Oil and Gas Operations

AI-powered predictive maintenance is revolutionizing how companies approach asset maintenance to ensure greater reliability, lower risks, and save costs.

Maintenance in the oil and gas industry has traditionally been scheduled at fixed intervals or as needed. This often results in excess maintenance or unanticipated outages. However, AI enables companies to quickly scan historical maintenance information and real-time operational data to predict equipment failures in advance and take action before they occur.

Machine learning tools can continually analyze the status of numerous pumps, drills, and compressors to identify patterns and notify operators of possible failures and malfunctions. This enables operators to proactively perform maintenance activities, such as replacing components that are about to fail.

Pipelines and refineries can also benefit from AI-based predictive maintenance. AI systems can examine data about the pipeline’s structural integrity and the refining process so companies can schedule maintenance at the optimum times to improve safety and equipment lifespans.

Using Digital Twins to Create a 1:1 Model

Digital twins are an innovative AI-based technology being implemented to support predictive maintenance. A digital twin is a digital replica of an in-field resource. The digital resource is continually updated with operational data, including maintenance history and operating information. Machine learning algorithms then identify anomalies to detect early signs of asset failure and enable operators to schedule maintenance.

Digital twins have other applications as well. Shell4 uses digital twins while developing deepwater oil and gas fields. It runs simulations and tests different configurations to ensure the infrastructure is optimized for safety and efficiency before actual construction. Meanwhile, Equinor5, a Norwegian energy company, uses digital twins of existing or planned oil and gas facilities to enable operators to fully understand the facilities’ performance and maintenance in a risk-free setting.

Using AI to Improve the Safety of Oil Refineries

Protection of personnel, equipment, and the environment are primary concerns in the oil and gas industry. AI-based predictive maintenance enables companies to detect problems and schedule maintenance before they become safety concerns. This reduces the risk of accidents and promotes safer working conditions for employees.

AI-based tools can also perform direct, real-time safety monitoring. Sensors can monitor equipment functioning, environmental conditions, and even worker activities. The AI tools can notify staff of any safety issues so corrective actions can be taken to prevent safety incidents.

In transportation, AI tools can determine optimal transportation routes for oil and gas products based on traffic and weather conditions to minimize the risk of accidents in transporting hazardous substances. The tools can analyze traffic, weather, and road data to locate the safest and most efficient transportation routes.

Safer Oil and Gas Operations Through Simulations

Immersive AI-powered simulations can create realistic environments in oil and gas facilities to enable operators to practice implementing safety procedures and responding to incidents like toxic leaks, fires, and critical equipment failures. This enables operators to become proficient at implementing standard protocols and saves the costs of physical mock-ups and live drills.

ExxonMobil has been a pioneer in AI-based simulations for training. In 2013, ExxonMobil Research Qatar6 co-created an immersive operator training simulator of a gas processing facility, including more than 300 interactive control devices.

The simulator depicts 3-D rotating valves and gauges and provides enhanced 4-D feedback, including tactile responses, odors, vibration, and wind. In 2015, ExxonMobil awarded EON Reality Inc. a global commercial license for the technology.

The Future of AI in Oil and Gas

AI promises significant process improvements and cost savings in the oil and gas industry. Multiple companies have made substantial investments in AI technology and are reaping benefits.

One challenge to the future adoption of AI is that companies will use the tools to augment their existing processes rather than transform their processes to exploit the tools’ potential fully. This challenge is across industries: Only 8% of companies engage in practices that support the wholesale adoption of AI7. Nevertheless, the AI market in oil and gas will continue to grow. Forecasts are for the AI market size in the oil and gas sector to increase from $3.14 billion in 2024 to $5.7 billion in 20297.

How Ambiq is Contributing

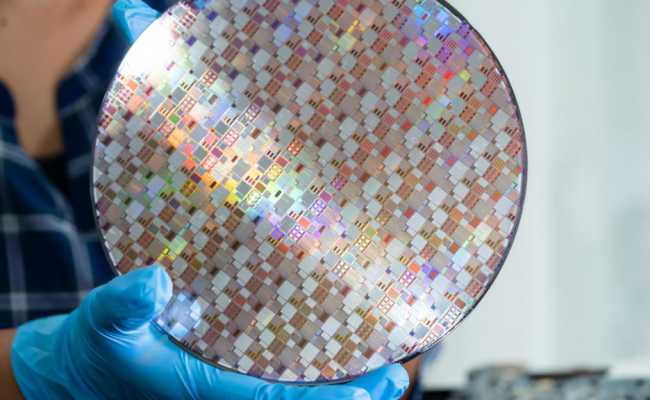

Smart sensors that can be used for predictive maintenance need to be embedded throughout an oil or gas site. They can be trained to collect and send data, alerting technicians about whether a machine is prone to failure based on sound, temperature, smell, or vibration. These sensors must be energy efficient and powerful enough to process edge AI industrial applications.

Ambiq features a variety of ultra-low power System-on-Chips (SoCs) that are meant to handle complex tasks such as predictive maintenance while drawing minimal energy from the sensors. Industrial sectors such as oil and gas can rest easy knowing they have reliable data that can warn them of potential problems before they become costly or catastrophic. Explore other applications for Ambiq here.

Sources:

1 Worldwide primary energy supply by source | Statista | June 28, 2024

2 Global Oil & Gas Exploration & Production – Market Size | IBISWorld | September 28, 2023

3 AI in Oil and Gas Industry: Benefits and Use Cases – Anadea | October 5, 2023

4 How Shell is fleshing out a digital-twin strategy | Computer Weekly | October 29, 2020

6 Immersive 3D Operator Training Simulator technology | ExxonMobil Qatar | July 8, 2019

8 AI in Oil and Gas Market – Artificial Intelligence – Trends & Companies (mordorintelligence.com) | 2024

7 Artificial intelligence in oil and gas upstream: Trends, challenges, and scenarios for the future – ScienceDirect | March 2021